A new view of Saddle shop made knife sheaths for the RMFT

Aug 28, 2014 12:12:42 GMT -7

Post by Chuck Burrows on Aug 28, 2014 12:12:42 GMT -7

Based on some of the trade lists we know that saddle shop made knife sheaths were available to the mountaineers:

Louis Labue…1 Belt Scabbard & Knife $0.87

Joseph Hardin…1 Belt & Scabbard .371/2

Joseph Hardin…1 knife 50c Belt & Scabbard 1$ 1.50

Henry Green…1 Belt & Scabbard .37 ½

Bought of Thornton Grimsley… ½ Doz Red painted Belts 6$ 3.00

Bought of Thornton Grimsley… 5 Belts & Scabbards .37 ½ 1.87 ½

Amt brought forward… 1 belt & scabbard 1.50

(1832, Papers of the St. Louis Fur Trade, Part 3: Robert Campbell Family Collection).

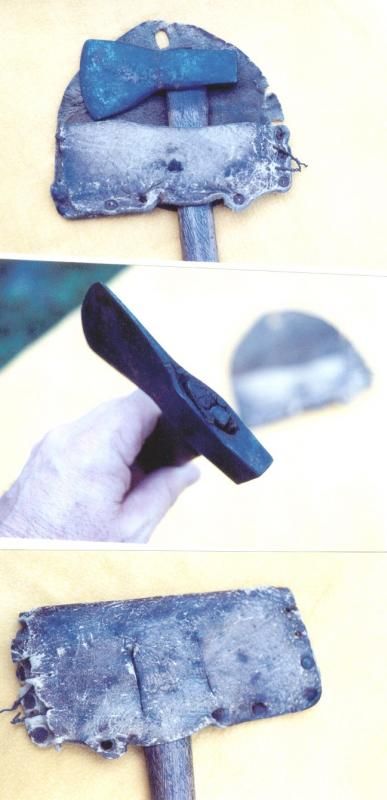

What exactly did these sheaths look like is of course the question. In several of A. J. Miller's prints we see simple sheaths stuck under the belt with what appears to be a single line of tacks along the outer edge. The idea of tacks has become pretty much the accepted view of most of us studying the era, an idea I never really questioned until a few years ago when I came across the following image of a knifesheath circa 1840 which appears to be a commercially made piece with small copper or brass rivets along the seam (size is most likely #14 - a common size of the time for smaller goods). The image is from the book "The Bowie Knife, Unsheathing an American Legend, by Flayderman.

What struck me about this sheath is in my opinion which FWIW is based on over 50 years of working on mostly historic repro leather goods (professionally since 1971) and studying the subject in depth, that this would likely be the more common method for a saddler/harness maker to use rivets rather than tacks for completing such a sheath. A welt would not be necessary and the rivets would be a fast method of construction. Speeding up the process would of course allow a less costly piece and one only has to note the prices listed above to see that low price was a factor.

While some sheaths of the period may have used tacks (although there are some extant early examples of sheaths with tacks per the Museum of the Fur Trade, tack usage in general is much more common post 1860 or so), the use of tacks was IMO more likely for in the field made sheaths. While this one example is by no means definitive proof for the use of rivets rather than tacks, I offer up the opinion that saddlery shop sheaths would have more commonly used rivets rather than tacks and that is what we may be/probably are seeing in those prints showing sheaths with a single line of them along the seam.

So what say you?

Louis Labue…1 Belt Scabbard & Knife $0.87

Joseph Hardin…1 Belt & Scabbard .371/2

Joseph Hardin…1 knife 50c Belt & Scabbard 1$ 1.50

Henry Green…1 Belt & Scabbard .37 ½

Bought of Thornton Grimsley… ½ Doz Red painted Belts 6$ 3.00

Bought of Thornton Grimsley… 5 Belts & Scabbards .37 ½ 1.87 ½

Amt brought forward… 1 belt & scabbard 1.50

(1832, Papers of the St. Louis Fur Trade, Part 3: Robert Campbell Family Collection).

What exactly did these sheaths look like is of course the question. In several of A. J. Miller's prints we see simple sheaths stuck under the belt with what appears to be a single line of tacks along the outer edge. The idea of tacks has become pretty much the accepted view of most of us studying the era, an idea I never really questioned until a few years ago when I came across the following image of a knifesheath circa 1840 which appears to be a commercially made piece with small copper or brass rivets along the seam (size is most likely #14 - a common size of the time for smaller goods). The image is from the book "The Bowie Knife, Unsheathing an American Legend, by Flayderman.

What struck me about this sheath is in my opinion which FWIW is based on over 50 years of working on mostly historic repro leather goods (professionally since 1971) and studying the subject in depth, that this would likely be the more common method for a saddler/harness maker to use rivets rather than tacks for completing such a sheath. A welt would not be necessary and the rivets would be a fast method of construction. Speeding up the process would of course allow a less costly piece and one only has to note the prices listed above to see that low price was a factor.

While some sheaths of the period may have used tacks (although there are some extant early examples of sheaths with tacks per the Museum of the Fur Trade, tack usage in general is much more common post 1860 or so), the use of tacks was IMO more likely for in the field made sheaths. While this one example is by no means definitive proof for the use of rivets rather than tacks, I offer up the opinion that saddlery shop sheaths would have more commonly used rivets rather than tacks and that is what we may be/probably are seeing in those prints showing sheaths with a single line of them along the seam.

So what say you?